Jansen Precision Technology

Jansen Precision Technology ontwikkelt en produceert zeer kleine en extreem nauwkeurige fijnmechanische onderdelen. Onze historie ligt in het zeer kleine en wij voelen daarvoor een ware passie. Door die passie en onze uitgebreide kennis ervaart u als klant een duidelijke meerwaarde bij het samen ontwikkelen, innoveren en door ons laten produceren van deze zeer-fijnmechanische onderdelen. U ervaart daardoor een gevoel van geruststelling en vertrouwen, zodat u zich volledig kunt concentreren op uw business en uw klanten. Welkom bij Jansen Precision Technology.

Speerpunten

Kwaliteit is een containerbegrip waar je bijna alles onder kunt scharen. Bij ons gaat kwaliteit vooral over aandacht. Een maatafwijking nagenoeg gelijk aan nul en verantwoorde zorg voor uw producten. Traceerbaarheid voor verantwoordelijkheid en kwaliteit geborgd door certificering. Wij zijn een bedrijf waar alles draait om slechts één gedachte: het best mogelijke product voor u als onze klant.

Wilt u daar eens over van gedachten wisselen? Neem dan gerust contact met ons op.

Markten

Medisch

Een oogchirurg, neurochirurg of andere medisch specialist werkt vaak tot op de halve millimeter nauwkeurig. Het operatiegereedschap is dan nog vele malen kleiner. Dat gereedschap moet probleemloos functioneren en prettig zijn om mee te werken. Daarnaast moet dat instrument goede garanties geven op het slagen van een medische ingreep.

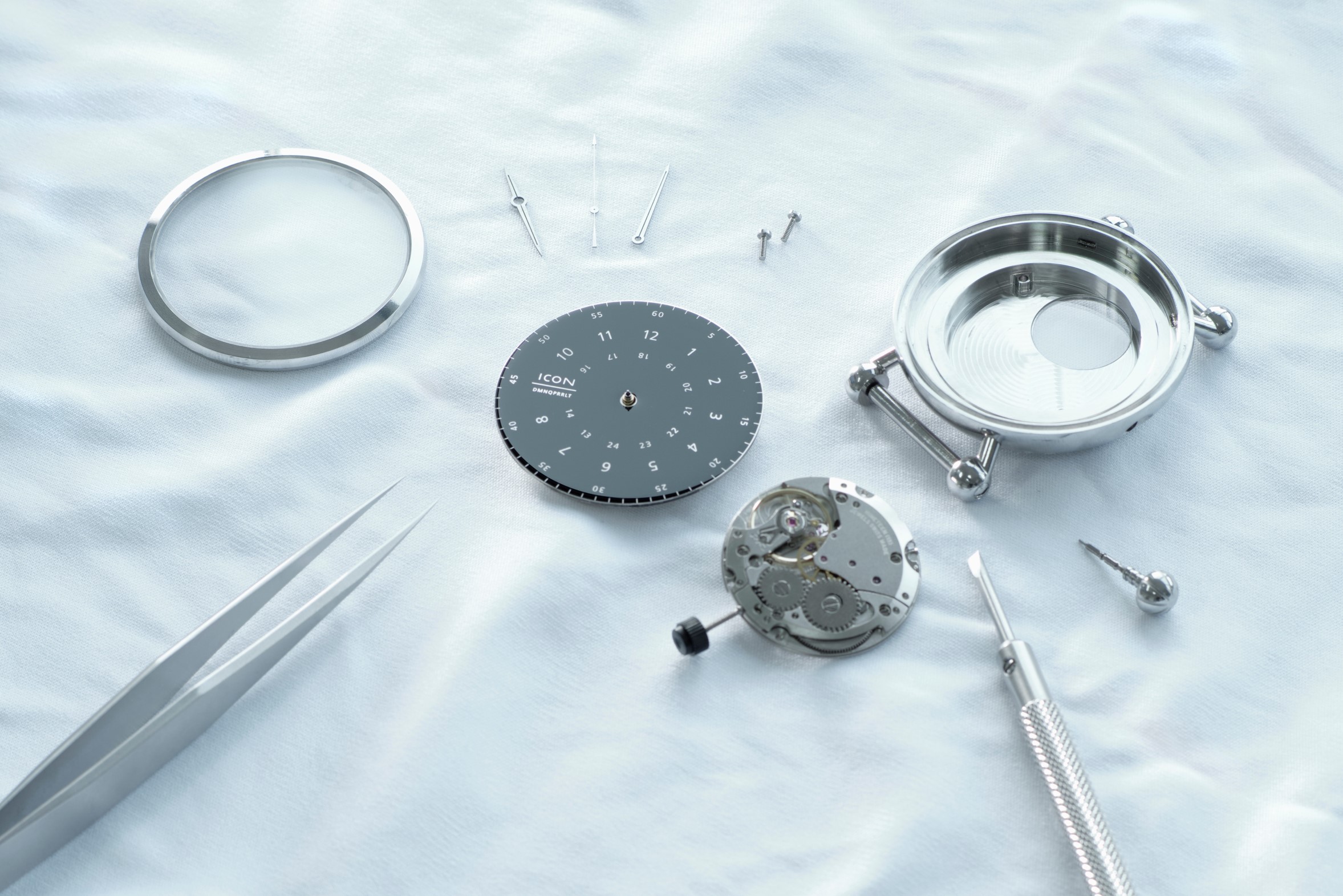

Uurwerk

Een uurwerkontwerper besteedt vele uren, hart en ziel in het ontwerp van het volmaakte uurwerk. Een uurwerk dat tientallen jaren tot op de milliseconde nauwkeurig loopt. Om dat te bereiken is het belangrijk dat de gebruikte radartjes, wijzers en andere kleine onderdelen een zeer hoog afwerkingsniveau hebben.

Inspiratie

Laat u inspireren door voorbeelden uit de wereld van het hele kleine en fijne. Blader of zoek op een specifieke toepassing, materiaal of bewerkingstechniek. Niet gevonden wat u zocht? Of juist zo geïnspireerd dat u meer wilt zien? Neem dan contact met ons op.

Lokalisatie marker

Lokalisatie marker (implantaat) bestaande uit enkele onderdelen samengesteld in een titanium behuizing. De behuizing is door middel van laserlassen hermetisch gesloten.

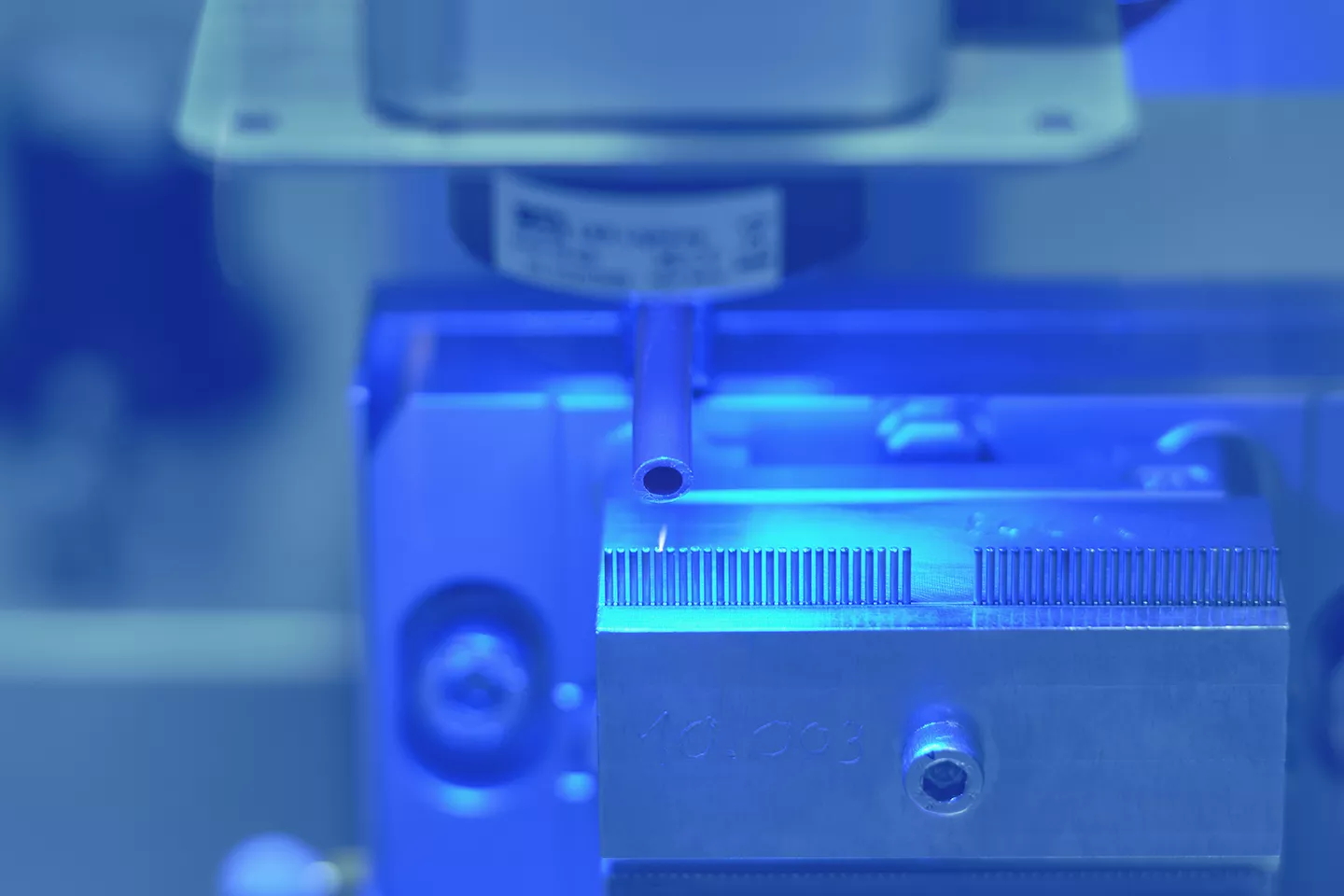

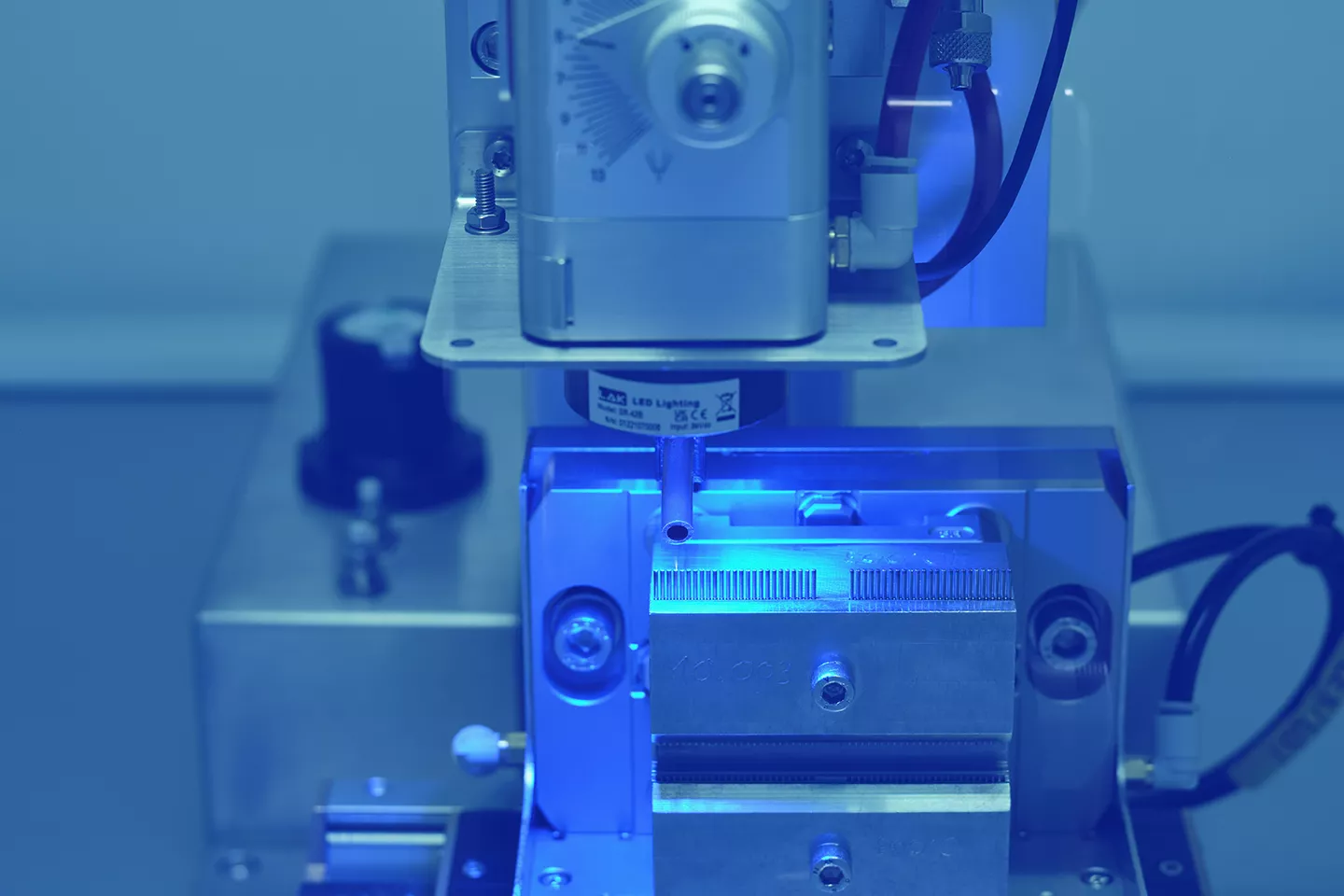

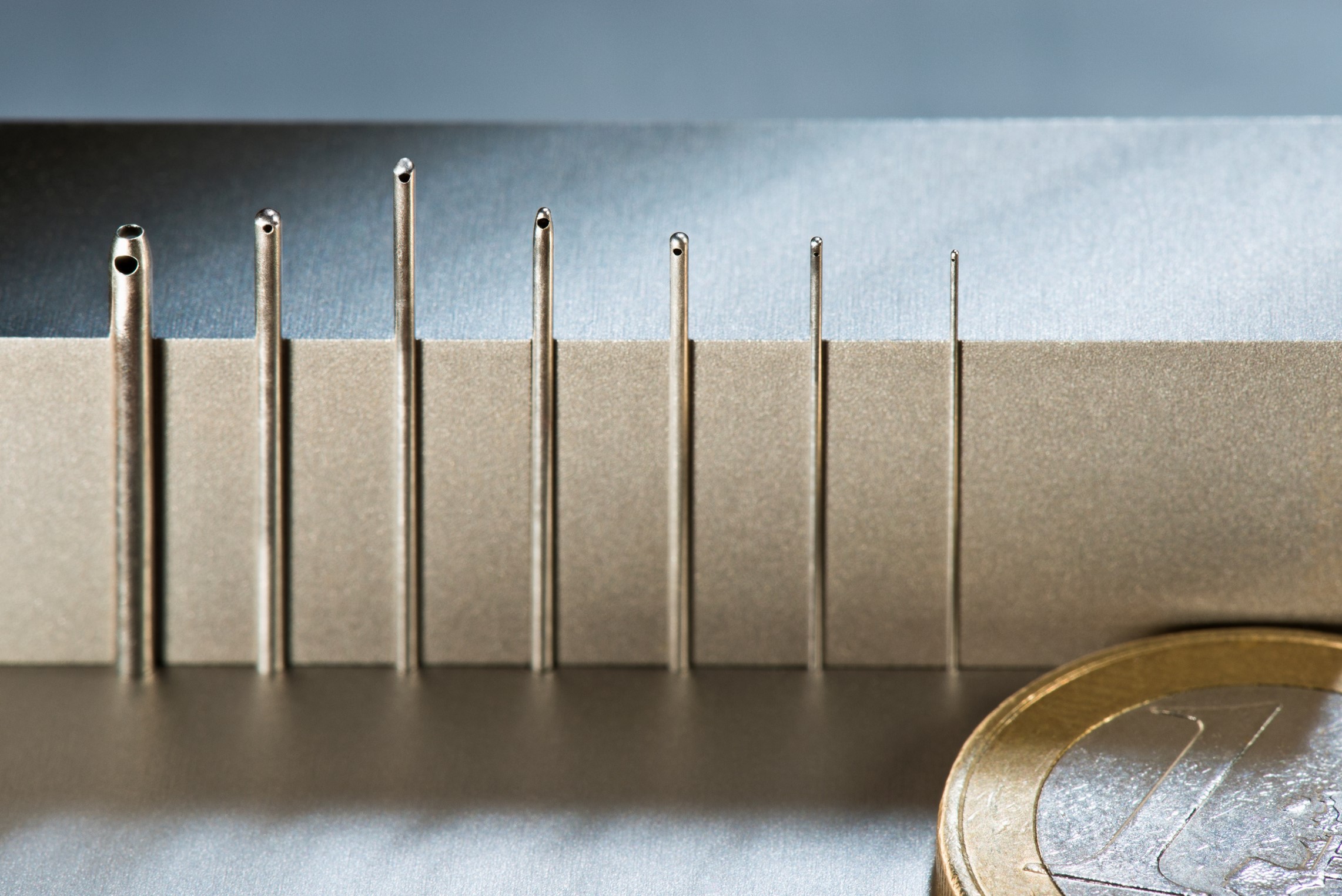

Diverse RVS capillairen

Diverse RVS capillairen in open of gesloten vorm. Voorzien van een klein gaatjeWerkwijze

Ontwikkeling

Na het ontstaan van een briljant idee, grote inspiratie of goed ontwerp blijkt vaak dat hele precieze fijnmechanische onderdelen nodig zijn. Die moeten ontwikkeld worden. Gelukkig werken bij Jansen Precision Technology de specialisten die weten welke grote rol die kleine onderdelen spelen. Samen met uw ontwikkelafdeling maken we een optimaal ontwerp. We selecteren materialen en houden rekening met een naadloze aansluiting op de latere productie. Zullen we samen die eerste stap zetten?

Productie

Ook bij productie van kleine series zijn duurzaamheid, kosten en levertijd belangrijk. Maar minstens zo belangrijk zijn gelijkheid en de kleinst mogelijke maatafwijking. Bij elk product in elke serie en keer op keer. De gepassioneerde specialisten van Jansen Precision Technology maken dat waar. Onze geconditioneerde productielocatie en de productie onder strenge ISO certificering garanderen de hoogst mogelijke kwaliteit met de kleinste maatafwijking in de markt. Wilt u met eigen ogen zien hoe dat werkt? Maak dan een afspraak voor een bezoek aan onze locatie.

Prototype

Meten is weten en zien is geloven. Oftewel, met een prototype van het ontwerp controleren we of de theorie in de praktijk gaat werken. Bij het prototype voor fijnmechanische delen gaan wij verder dan de bouw alleen. Wanneer nodig ontwerpen en bouwen we zelfs ons eigen gereedschap om het prototype te ontwikkelen en maken. Het spreekt voor zich dat wij samen met u tegelijk onderzoeken of het ontwerp effectief en tegen acceptabele kosten in serie te produceren is. Weten hoe dat werkt? Laten we kennismaken.